(6120 products available)

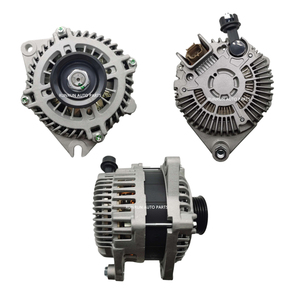

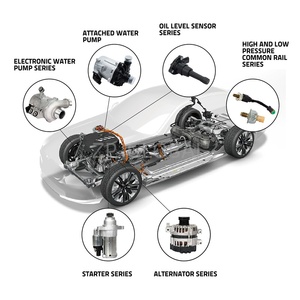

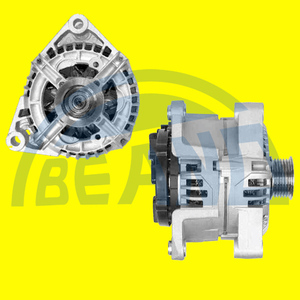

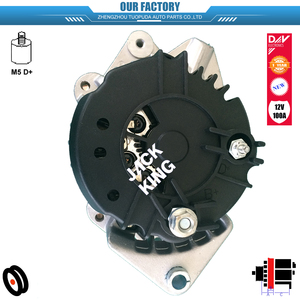

A B alternators come in various sizes and types. Each type has its unique features that suit specific needs and applications. Some common types of A B alternators are

1. Brushless alternators

A brushless alternator uses electromagnetic induction to produce electricity. They are mainly used on big trucks and in industrial settings where huge power is required. The most exciting thing about these alternators is that they don't have brushes. As a result, they don't require frequent replacement or maintenance, unlike other alternators that use brushes. In addition, they are very reliable and generate high-quality power, making them ideal for critical applications.

2. Wound rotor alternators

These alternators have a rotor with windings connected to the external excitation source through slip rings and brushes. The winding on the rotor acts as an electromagnet. When the rotor is rotated by a prime mover, a magnetic field is produced. This magnetic field causes a current to flow in the stator windings.

3. Synchronous condensers

A synchronous condenser is a synchronous motor that runs above the synchronous speed. It is used to improve the power factor in the power system by absorbing or generating reactive power. Synchronous condensers help in voltage regulation and increase the system's stability.

4. Permanent magnet alternators

These alternators use permanent magnets to generate the magnetic field instead of using electromagnets. This design eliminates the need for an external excitation system. Permanent magnet alternators have higher efficiency and lower maintenance requirements. They are commonly used in wind turbines, hydroelectric systems, and other renewable energy applications.

5. 2-pole and 4-pole alternators

The number of poles on the rotor defines the type of A B alternators. 2-pole alternators have 2 magnetic poles (North and South) on the rotor, while 4-pole alternators have 4 magnetic poles (2 North and 2 South) on the rotor. 2-pole alternators generate a higher frequency of electrical output. On the other hand, 4-pole alternators are more common and widely used in various applications.

Regular Inspection

Regular inspections are essential for A B alternator maintenance. Loose bolts, broken mounts, and other physical alternator issues are examined during routine inspections. The wiring and connections of the alternator are visually examined for any indications of damage or corrosion. To guarantee appropriate current flow, all connections are checked to be tight and secure. Any odd noises coming from the alternator are listened to, which may point to internal component wear or failure. The alternator's performance is observed to make sure it consistently produces the right output voltage and current. The alternator is inspected for any warning lights or dashboard indicators that may be triggered by alternator problems. Regular inspections enable early identification of potential alternator problems, enabling prompt corrective action before major failures happen.

Keeping the Alternator Clean

AB alternators need to be cleaned in order to guarantee effective and dependable operation. Dust, dirt, and debris accumulation on the alternator's exterior may reduce heat dissipation, increasing the risk of overheating. The ab alternator is gently cleaned using a soft brush to remove any loose debris. A damp cloth is used to wipe the alternator's exterior surfaces clean. Compressed air is used to blow off any accumulated dirt from the alternator's nooks and crannies. Cleaning is done carefully to avoid getting any liquids inside the alternator that might harm the internal components. The alternator's vents and cooling fins are examined for any blockages or restrictions, and they are cleaned to maintain proper airflow. A b alternators can be prevented from being hampered by pollutants and maintained in peak condition by routine cleaning.

Inspecting and Replacing Belts

A b alternators require proper tension and alignment of the drive belts for efficient operation. The belts are visually examined for indications of wear, such as cracks, fraying, or glazing. Uneven wear patterns or damage to the belts may be caused by faulty pulley alignment or overloading. The belt tension is checked to ensure it meets the manufacturer's specifications. A loose or overtensioned belt can lead to alternator problems or premature belt failure. The belts are inspected for unusual noises, such as squeaking or slipping sounds, indicating potential issues. If required, the belts are adjusted for proper tension and alignment. Any worn or damaged belts are replaced to prevent potential alternator and accessory drive system issues. Regular belt inspections and maintenance ensure reliable power transmission from the engine to the alternator.

Monitoring Performance

Monitoring the performance of A B alternators is a crucial aspect of their maintenance. The voltage and current output of the alternator are regularly checked using a multimeter. This ensures that the alternator is delivering the necessary electrical power to the vehicle's systems. The performance of the alternator is compared to the manufacturer's specifications. Any deviations from the specified output may indicate internal wear or damage. The charging performance of the alternator is monitored, especially under load conditions. This ensures that the alternator can maintain the battery's charge even when powering additional electrical accessories. The temperature of the alternator is periodically measured, as overheating can lead to reduced performance or premature failure. Changes in performance over time are tracked, and trends are analyzed. This allows for proactive maintenance actions before critical alternator problems occur.

Choosing the right and suitable A B alternator for any vehicle or equipment is a crucial decision that can impact performance, durability, and reliability. Here are some key factors to consider when selecting A B alternators:

Replacing a B alternator is a straightforward task that can be accomplished with basic mechanical skills. The following are steps on how to DIY and replace a B alternator:

Tools Needed

Step-By-Step Guide

Q1: Are ball-bearing A B alternators better than other A B alternator types?

A1: A b alternator with ball bearings is not necessarily better, but it has its advantages. A, B alternators with ball bearings are more durable and require less maintenance. They can handle high speeds and have a smoother operation, which makes them last longer.

Q2: Can one upgrade to a larger A B alternator for more electrical output?

A2: Yes, it is possible to upgrade to a larger A, B alternator. A larger A B alternator will provide more electrical output, which is beneficial if one has added accessories or electrical components to the vehicle. However, it is important to ensure that the alternator is compatible with the vehicle's system.

Q3: Why are A B alternators more commonly used in heavy-duty trucks?

A3: A B alternators are more commonly used in heavy-duty trucks because they are more efficient and can produce a lot of electrical power. Trucks have many electrical components that need reliable power, and A B alternators can handle that task.

Q4: Do A B alternators require regular maintenance?

A4: Yes, A B alternators require regular maintenance, although they are generally low-maintenance. Users should routinely check the A B alternator belts for proper tension and wear and keep the alternator clean and free of debris. Battery terminals should also be clean and tight to ensure good connectivity.

Q5: Can one use A B alternators in marine applications?

A5: Yes, A B alternators can be used in marine applications. However, it is important to choose alternators that are designed for marine use, as they will be better suited to withstand the corrosive environment of saltwater.