(5085 products available)

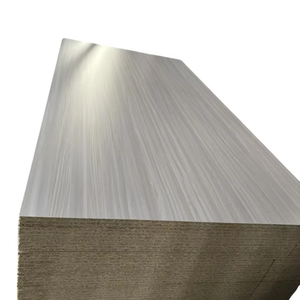

A 4x8 sheet of MDF (Medium Density Fiberboard) is a popular engineered wood product used in various construction and design projects. It is valued for its smooth surface, versatility, and cost-effectiveness. Here are some types of 4x8 sheets of MDF:

Standard MDF:

Standard MDF is a commonly used 4x8 sheet of MDF. It is made from wood fibers, wax, and resin compressed into a dense board. This type is smooth, flat, and easy to work with. It is used in applications such as cabinetry, furniture, and decorative wall panels.

Moisture-Resistant MDF:

Moisture-Resistant MDF is specifically designed for areas where humidity or moisture is a concern. It contains additives that help prevent the growth of mold and mildew. This type is ideal for bathrooms, kitchens, and other damp environments. In some markets, it is known as green MDF due to its characteristic green coating.

Fire-Retardant MDF:

Fire-Retardant MDF is manufactured with fire-resistant chemicals. These chemicals are added during the production process. This results in a board that meets specific building codes and regulations for fire safety. It is commonly used in commercial properties and areas requiring fire-rated materials.

High-Density MDF:

High-Density MDF is manufactured to be denser than standard MDF. It is created by increasing the amount of wood fibers and resin in the mixture. The result is a heavier and more durable board. This type is used for applications that require extra strength and stability, such as solid-core doors and heavy-duty furniture.

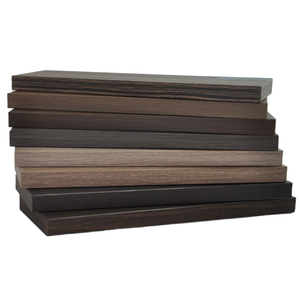

veneered MDF:

Veneered MDF is a sheet of Medium Density Fiberboard that has been veneered with natural wood veneer on one or both sides. It combines the benefits of MDF with the appearance of a solid wood surface. The veneer provides a more aesthetically pleasing finish for applications such as drawers, cabinet fronts, and furniture surfaces.

Pre-Primed MDF:

Pre-Primed MDF has a primer coat applied to its surface during manufacturing. This process helps to enhance the adhesion of paints and finishes. It saves time in the finishing process. Pre-Primed MDF is commonly used for moldings, trims, and custom built-ins that require a painted finish.

Wrapped MDF:

Wrapped MDF is a type of MDF that has been wrapped in vinyl or foil on its surfaces and edges. This process creates a finished product that is more visually appealing and easier to maintain. Wrapped MDF is commonly used for doors, countertops, and cabinetry in areas where a decorative surface is required.

MDF 4x8 sheets are commonly used in construction and woodworking projects due to their versatility and ease of use. Here are some common applications:

Furniture Construction

Due to its smooth surface and stability, MDF is frequently used to make furniture pieces such as cabinets, drawers, tables, and chairs. It allows intricate designs and reliable surfaces for painting or varnishing.

Interior Design

MDF sheets are used to construct built-in wardrobes, entertainment centers, and shelving units. Their adaptability enables the design of bespoke storage solutions that fit various spaces and requirements.

Decorative Wall Panels

4x8 MDF sheets can be cut into panels and detailed with moldings. They can also be painted or textured to serve as elegant and dramatic wall coverings. These panels add character to a room and are a cost-effective option compared to real wood panels.

Crown Molding and Trim Work

MDF is used to make crown molding, baseboards, and door casings because of its smooth finish and ability to replicate detailed designs. These MDF moldings are less expensive than traditional wood moldings but provide a polished appearance.

Cabinet and Drawer Fronts

Cabinet doors, drawer fronts, and decorative accents within cabinets are made of MDF. The material's smooth surface makes it excellent for painting, resulting in fashionable and tailored kitchen and bathroom areas.

Customizable Artwork and Signage

The 4x8 MDF sheets are favored by artists and designers for making bespoke artwork, wall decors, and signage. The smooth surface and rigidity of the material provide reliable supports for painting, engraving, or laser-cutting.

Underlayment

MDF sheets can be used as underlayment for floating or glued-down flooring. They offer a smooth surface for flooring installation and assist in noise reduction and leveling imperfections in the subfloor.

Craft and Hobby Projects

Small MDF pieces are often used in craft and hobby projects. Crafters can create photo frames, miniatures, coasters, and customized decorations. The ease with which it can be cut and shaped makes it a favorite among hobbyists.

There are many scenarios where MDF is used in construction, and knowing them helps one understand the product better. Here are some common usage scenarios for MDF:

There are many factors to consider when choosing the right MDF sheets for sale. The target market has different needs, so it is important to understand them before purchasing the MDF sheets. Here are some of the things that should be considered.

Thickness

The thickness of the MDF sheets affects their use. The thickness varies from 3mm to 25mm. Thin MDF sheets are used for model making, while thick ones are used for building cabinets and furniture. In this case, it is important to choose the right thickness for the intended purpose.

Type

MDF sheets are of different types, and each type has its own use. The standard MDF is the most common and is used for general construction. The moisture-resistant MDF is used in areas with high humidity, like bathrooms and kitchens. The fire-retardant MDF is treated with chemicals to reduce its flammability, and it is used in areas where building codes require fire-resistant materials. The veneered MDF comes with a pre-applied veneer that improves its aesthetic appearance. The embossed MDF has an embossed surface design and is used for decorative applications. The plastic-coated MDF has a plastic coating that makes it more durable and easy to clean. The foil-coated MDF has a foil coating that provides a decorative finish. It is important to choose the right type of MDF sheets to meet the customer's needs.

Edge Treatment

The edge treatment of the MDF sheets affects their appearance and performance. The beveled edges reduce the gap between sheets during installation, while the square edges provide a clean and sharp look. The tappered edges reduce the amount of filler material needed in the joints, while the rounded edges reduce the risk of chipping or damage. When selecting the MDF sheets, it is important to choose the right edge treatment that will meet the customer's needs.

Quality

The quality of the MDF sheets affects their performance. High-quality MDF sheets have a smooth surface, uniform density, and well-defined edges. They are easy to work with and produce high-quality finished products. Low-quality MDF sheets have a rough surface, inconsistent density, and poorly defined edges. They are difficult to work with and produce low-quality finished products. It is important to choose high-quality MDF sheets to ensure that the customers are satisfied.

Q1: What does the term ""MDF"" stand for?

A1: The term ""MDF"" means Medium Density Fiberboard. It is a type of engineered wood product formed by breaking down wood into fine fibers.

Q2: What are the key characteristics of MDF?

A2: MDF features a smooth surface, uniform density, and excellent machinability. It is usually more stable and easier to work with than solid wood.

Q3: Is MDF a good material for furniture?

A3: Yes, MDF is a good choice for budget-friendly furniture construction. It provides a smooth surface for veneers and laminates, offering aesthetic flexibility.

Q4: Is MDF waterproof?

A4: Standard MDF is not waterproof. It is susceptible to moisture damage. However, there are waterproof variants like MDF moisture-resistant that are suitable for humid environments.

Q5: Does MDF emit formaldehyde?

A5: Most MDF boards emit formaldehyde. This compound is released during the manufacturing process and can be harmful when inhaled. MDF boards are classified based on their formaldehyde emission levels.

Q6: How should MDF be finished?

A6: To finish MDF, use paint, veneer, or laminate. Primer and paint work well for edges and surfaces. Veneer and laminate provide attractive, durable options.

Q7: What tools are needed to cut MDF?

A7: Circular saw, jigsaw, table saw, and hand saw work well to cut MDF. Use carbide-tipped blades for clean edges.

Q8: Can MDF be sanded and drilled?

A8: Yes, MDF can be sanded to achieve a smooth finish. It can also be drilled to create holes for screws and fittings. Use the appropriate grit sandpaper and drill bits.

Q9: Is it difficult to assemble MDF parts?

A9: No, assembling MDF parts is not complicated. Use screws, wood glue, cam locks, and other fittings. Follow the manufacturer's recommendations for best results.

Q10: Are there different types of MDF?

A10: Yes, there are several types of MDF. They include; standard MDF, moisture-resistant MDF, and fire-retardant MDF. Standard MDF is used for general-purpose applications. Moisture-resistant MDF is designed for areas with high humidity, like kitchens and bathrooms. Fire-retardant MDF is treated with fire-inhibiting chemicals to reduce its flammability.