Types of 4G63 Evo Engine

The 4G63 Evo engine is a four-cylinder, inline, water-cooled, four-stroke internal combustion engine. This legendary 2.0-liter powerplant from the 4G6 engine family was first introduced in 1985 and powered various Mitsubishi and Chrysler vehicles until the late 1990s. The 4G63 Evo engine gained iconic status through its use in the first four generations of the Mitsubishi Lancer Evolution, making it a highly sought-after choice among performance enthusiasts and tuners worldwide.

4G63 Cast Iron Block

The cast iron block variant features exceptional durability and thermal stability. Its robust construction can withstand high temperatures and pressures, making it ideal for high-stress applications.

Best for: Reliability, durability, and handling high power outputs

Characteristics: Higher weight, excellent strength, less prone to cracking

4G63 Aluminum Alloy Block

The aluminum alloy block offers significant weight reduction compared to its cast iron counterpart. This lightweight construction improves overall vehicle weight distribution and performance.

Best for: Racing applications, improved responsiveness, quicker revs

Characteristics: Lighter weight, better heat dissipation, requires more careful tuning

4G63 Turbo Engine

The turbocharged variant utilizes exhaust gases to drive a turbine, compressing incoming air for increased power and efficiency. This forced induction system dramatically increases performance capabilities.

Best for: High performance applications, tuning potential, increased power

Characteristics: Significant power increase, turbo lag, greater tuning potential

4G63T

The 4G63T is the factory-turbocharged version featuring DOHC configuration. This variant established Mitsubishi's reputation for high-performance engines and powered multiple championship-winning rally cars.

Best for: Maximum performance, motorsport applications

Characteristics: Factory optimized turbo system, high power potential, robust construction

Expert Insight: The 4G63 Evo engine's cast iron block version is often preferred for extreme high-horsepower builds (500+ HP) due to its superior strength under high boost pressures, while the aluminum variant offers better performance characteristics for balanced, daily-driven builds under 450 HP.

Specifications and Technical Details

The 4G63 Evo engine earned its reputation through impressive technical specifications that provided an excellent foundation for both stock performance and aftermarket modifications. While specifications vary slightly between generations, these engines share core design elements that contribute to their legendary status.

| Specification | Details | Notes |

|---|---|---|

| Displacement | 2.0 liters (1997 cc) | Optimal balance between response and power |

| Configuration | Inline-4 | Compact design for improved weight distribution |

| Valvetrain | DOHC 16-valve | Dual Overhead Camshaft for improved breathing |

| Turbocharger | T25/TD05H-16G (varies by model) | Factory turbo with excellent response characteristics |

| Fuel System | Electronic fuel injection | Precise fuel delivery for optimal performance |

| Ignition System | Distributorless (DISI) | More reliable than traditional distributor systems |

| Compression Ratio | 8.8:1-9.0:1 | Lower ratio to accommodate forced induction |

| Bore x Stroke | 85 mm x 88 mm | Slightly undersquare design for improved torque |

| Peak Power | 135-280 hp (varies by model) | Later Evo models offered increased factory power |

| Peak Torque | 190-300 Nm (varies by model) | Excellent torque delivery throughout rev range |

| Transmission | 5-speed/6-speed manual | Robust transmissions designed for performance use |

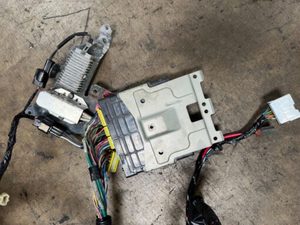

| Engine Control | Electronic Control Unit (ECU) | Highly tunable for increased performance |

Performance Note: The 4G63 Evo engine's "square" bore and stroke design (both nearly equal) provides an excellent balance between low-end torque and high-RPM power, making it versatile for both street driving and track use. This design also contributes to its exceptional tuning potential.

Maintenance and Care Guidelines

Proper maintenance is crucial for maximizing the performance, reliability, and longevity of the 4G63 Evo engine. Following these specialized maintenance procedures will help ensure your engine remains in optimal condition for years to come.

Regular Maintenance

- Premium Engine Oil: Use high-quality synthetic oil (5W-30 or 5W-40) specifically rated for turbocharged engines

- Oil Change Interval: Every 3,000-5,000 miles for performance applications

- Oil Filter: Replace with each oil change using OEM or high-quality aftermarket filters

- Air Filter: Inspect every 5,000 miles, replace every 15,000 miles or as needed

Performance Components

- Spark Plugs: Replace every 20,000-30,000 miles with copper or iridium plugs

- Ignition Coils: Inspect every 30,000 miles for signs of failure

- Timing Belt: Critical maintenance - replace every 60,000 miles without exception

- Turbocharger: Check for play in the shaft and oil leaks every 15,000 miles

| Maintenance Task | Frequency | Importance | Notes |

|---|---|---|---|

| Engine Oil & Filter | 3,000-5,000 miles | Critical | Use fully synthetic oil rated for turbocharged engines |

| Cooling System Flush | 30,000 miles | High | Use manufacturer-specified coolant only |

| Timing Belt & Water Pump | 60,000 miles | Critical | Catastrophic failure if neglected |

| Fuel Filter | 30,000 miles | Medium | More frequently if using poor quality fuel |

| Spark Plugs | 20,000-30,000 miles | High | Use correct heat range for your modifications |

| Valve Lash Adjustment | 45,000 miles | Medium-High | Critical for optimal performance and longevity |

| Turbo Inspection | 15,000 miles | High | Check for shaft play and oil leaks |

Critical Warning: The timing belt on 4G63 Evo engines is an interference design - if it fails, valves will contact pistons, causing catastrophic engine damage. Never exceed the 60,000-mile replacement interval, and consider replacement at 50,000 miles for modified engines under higher stress.

How to Choose a 4G63 Evo Engine

Selecting the right 4G63 Evo engine requires careful consideration of multiple factors including intended use, budget, and compatibility with your vehicle. This comprehensive selection guide will help you make an informed decision when purchasing this legendary powerplant.

Compatibility Factors

Ensure complete system integration with your vehicle's existing components:

- Engine mounting points and hardware

- Transmission compatibility and bellhousing alignment

- Exhaust system configuration and clearance

- Cooling system capacity and radiator specifications

- ECU and wiring harness integration requirements

Performance Requirements

Match engine specifications to your performance goals:

- Daily driver: Stock or mildly modified (250-300hp)

- Weekend warrior: Moderately upgraded (300-400hp)

- Track/competition use: Heavily modified (400hp+)

- Consider torque characteristics for your driving style

- Evaluate throttle response vs. peak power needs

Budget Considerations

Plan for all associated costs:

- Initial engine purchase (varies widely by condition)

- Supporting modifications (intake, exhaust, cooling)

- Installation costs if not DIY

- Engine management (stock ECU vs. aftermarket)

- Ongoing maintenance requirements

Sourcing Advice: When purchasing a used 4G63 Evo engine, always request compression and leak-down test results. These tests provide crucial information about internal engine health that visual inspection alone cannot reveal. Documentation of maintenance history is equally valuable and can indicate potential problem areas.

Key Selection Criteria Checklist

| Criteria | Importance | What to Look For |

|---|---|---|

| Engine Generation | High | Later generations (Evo III, IV) typically offer improved components |

| Compression Test | Critical | All cylinders should read within 10% of each other (ideal: 180+ psi) |

| Oil Pressure | Critical | Should maintain 40+ psi at operating temperature |

| Timing Belt Age | High | Verify recent replacement or budget for immediate service |

| Turbocharger Condition | High | Check for shaft play, oil leaks, or compressor wheel damage |

| Modification History | Medium-High | Professional modifications generally better than DIY |

| Environmental Impact | Medium | Consider emissions compliance for your region |

DIY Engine Replacement Guide

Replacing a 4G63 Evo engine can be a rewarding DIY project with proper preparation, tools, and knowledge. This step-by-step guide will walk you through the complete engine replacement process, helping you avoid common pitfalls and ensure a successful installation.

Safety Warning: Engine replacement involves heavy components and hazardous fluids. Always use proper lifting equipment, jack stands, and safety gear. Never work under a vehicle supported only by a jack. Disconnect the battery before beginning any work.

Required Tools and Materials

- Engine hoist (cherry picker) with minimum 1-ton capacity

- Engine stand for preparation work

- Complete socket and wrench set (metric)

- Torque wrench for critical fasteners

- Jack and jack stands rated for your vehicle's weight

- Drain pans for fluids

- New gaskets, seals, and fasteners as needed

- Factory service manual for torque specifications

- Replacement fluids (oil, coolant, etc.)

Step-by-Step Replacement Process

- Prepare your workspace - Ensure you have a clean, well-lit garage or workspace with sufficient room around the vehicle. Lay down floor mats to catch fluid drips and provide a clean working environment.

- Document and photograph everything - Before disconnecting anything, take detailed photos of all connections, hose routings, and wiring harness positions. This will be invaluable during reassembly.

- Disconnect the battery - Always disconnect the negative battery terminal first, followed by the positive terminal to prevent electrical shorts or damage to the vehicle's electronics.

- Drain all fluids - Properly drain engine oil, coolant, and transmission fluid if necessary. Dispose of all fluids according to local regulations.

- Remove peripherals and connections - Systematically disconnect and label all:

- Electrical connections and sensors

- Vacuum lines and fuel lines

- Intake and exhaust components

- Cooling system hoses and connections

- Accessory drive components

- Separate transmission from engine - Support the transmission with a jack before removing the bellhousing bolts to prevent damage to the input shaft.

- Attach engine to hoist - Secure the engine to the hoist using proper lifting points. Double-check all connections before applying tension.

- Remove engine mount bolts - Once the engine is supported by the hoist, remove the engine mount bolts carefully.

- Extract the engine - Slowly and carefully lift the engine, checking for any remaining connections. Pause frequently to ensure nothing is caught or still attached.

- Prepare the new engine - Transfer necessary components from the old engine if using a bare block, or prepare the complete replacement engine by checking all fluid levels and connections.

- Install the new engine - Lower the engine carefully into position, aligning with mounting points and transmission input shaft.

- Secure engine mounts - Tighten engine mount bolts to factory torque specifications.

- Reattach all connections - Work in reverse order, referring to your documentation and photos to ensure proper routing of all hoses, wires, and mechanical connections.

- Refill all fluids - Add fresh engine oil, coolant, and transmission fluid as needed.

- Perform pre-start checks - Before starting:

- Verify all connections are secure

- Check for proper fluid levels

- Ensure no tools or materials are left in engine bay

- Reconnect battery (positive terminal first, then negative)

- Initial start and testing - Start the engine and check immediately for:

- Oil pressure reading

- Unusual noises

- Fluid leaks

- Proper idle and throttle response

Professional Insight: Allow a newly installed 4G63 Evo engine to go through a proper break-in period. Keep RPMs under 4,000 for the first 500 miles, avoid sustained high speeds, and vary engine load frequently. Change the oil after the first 500 miles to remove any metal particles from the initial break-in process.

Frequently Asked Questions

Yes, the 4G63 Evo engine can be installed in various other vehicles beyond the Mitsubishi Lancer Evolution. However, successful transplants require careful assessment of compatibility factors including engine mount locations, transmission fitment, wiring harness integration, and cooling system capacity. Popular swap candidates include Mitsubishi Eclipse/Eagle Talon, Galant VR-4, and even some non-Mitsubishi platforms with appropriate modification. Professional engine mounting kits are available for common swaps to simplify the process.

The 4G63 Evo engine requires more frequent maintenance than typical passenger car engines due to its performance-oriented design. Key maintenance intervals include:

- Engine oil and filter: Every 3,000-5,000 miles (synthetic oil recommended)

- Air filter: Inspection every 5,000 miles, replacement as needed

- Spark plugs: Every 20,000-30,000 miles (less for modified engines)

- Timing belt: Critical replacement at 60,000 miles maximum

- Valve lash adjustment: Every 45,000 miles

- Turbocharger inspection: Every 15,000 miles

- Cooling system flush: Every 30,000 miles

Modified engines with increased power output typically require more frequent service intervals proportional to the level of modification.

Several warning signs may indicate potential issues with your 4G63 Evo engine:

- Decreased power and acceleration: Often the first sign of engine problems, particularly if accompanied by irregular boost behavior

- Unusual noises: Rod knock (low, rhythmic knocking), piston slap (more pronounced when cold), or timing chain rattle require immediate attention

- Excessive exhaust smoke: Blue smoke indicates oil burning (possible valve seals or piston rings), white smoke suggests coolant entering combustion chambers (potential head gasket failure)

- Warning lights: Check engine light, oil pressure, or temperature warnings should never be ignored

- Oil consumption: Using more than 1 quart of oil per 1,000 miles indicates internal wear

- Coolant loss: May indicate head gasket failure, especially if accompanied by overheating

- Turbo lag or boost issues: Could indicate turbocharger problems or wastegate/boost control issues

Address any of these symptoms immediately to prevent catastrophic engine failure.

The 4G63 Evo engine offers an excellent platform for beginners in the world of car tuning for several reasons:

- Robust design: The factory engine block and internals can handle moderate power increases without requiring internal modifications

- Extensive community support: Vast online resources, forums, and tutorials specifically for 4G63 tuning

- Gradual modification path: Allows for incremental upgrades starting with simple bolt-ons before advancing to more complex modifications

- Forgiving nature: More tolerant of tuning errors than some more exotic engines

- Aftermarket availability: Extensive selection of quality performance parts at various price points

Beginners should start with basic bolt-on modifications (intake, exhaust, intercooler) and proper tuning before considering internal engine modifications or significantly increased boost pressure.

Yes, the 4G63 Evo engine can be modified to run on various alternative fuels with the appropriate modifications:

- Ethanol blends (E85): Most common conversion, requires larger fuel injectors (30-40% larger), upgraded fuel pump, fuel lines, and proper ECU tuning. Offers significant performance benefits with cooler combustion temperatures.

- Methanol/Water Injection: Can be added as a supplemental system to reduce detonation and increase power, particularly useful for heavily boosted applications.

- Propane: Requires specialized conversion kit including dedicated fuel system, pressure regulator, and injection system. Less common but provides clean-burning characteristics.

- Compressed Natural Gas (CNG): More complex conversion requiring high-pressure tanks, regulators, and significant fuel delivery modifications. Primarily benefits emissions rather than performance.

E85 conversion is the most popular option as it offers substantial performance benefits with relatively straightforward modifications. Professional tuning is essential for any alternative fuel conversion to ensure proper air/fuel ratios and timing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4