Types of 380v water-cooled chillers

A 380v water-cooled chiller is a central chiller system that uses water as a coolant. It is mainly suitable for large customers with large refrigeration needs. Generally, 380V water-cooled chillers have four main systems to choose from, such as screw chillers, centrifugal chillers, and absorption chillers.

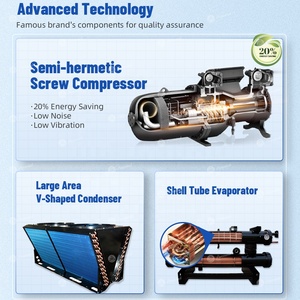

- Screw chillers: A refrigerant compression chillers system with an electric screw compressor. The core components are rotors that compress and refrigerate the gas directly. The technology cools the water via a heat exchange process between the refrigerant and the water .

- Centrifugal chillers: They are also known as direct-drive chillers. The compressor, which is driven by a turbine, compresses the refrigerant to create a cooling effect. Centrifugal chillers work based on the same theory as centrifugal force.

- Absorption chillers: This kind of chiller absorbs heat released from water and gets it from an external source through a chemical process. The absorption chiller consists of a refrigerant and an absorbent. The heat causes the coolant to evaporate, and then the vapor cools and refrigerates the space.

Specification And Maintenance Of 380V Water Cooled Chillers

Water-cooled chillers are normally rated by their cooling capacities. The units are also specified by certain key component characteristics.

- Cooling Capacity: The amount of heat a chiller can absorb from a process or space per unit of time, typically measured in kilowatts (kW) or British Thermal Units per hour (BTU/h).

- Operating Temperature Range: The range of temperatures at which the chiller can operate effectively. This includes the inlet and outlet temperature dimensions of the fluid being cooled. For water-cooled chillers, the temperature range generally is 7-12 °C.

- Refrigerant Type: The type and specification of the refrigerant the chiller uses. It must be selected to ensure compatibility with the chiller's design and environmental considerations.

- Energy Efficiency Ratio (EER): The ratio of cooling capacity to energy consumption, which measures the chiller's energy efficiency. A higher EER indicates better energy efficiency and lower operating costs.

- Voltage and Power: The voltage and power requirements of the chiller, including operating voltage, current, and power rating, for proper electrical connections and power supply.

- Dimensions and weight: The size and weight of the chillers for installation space and handling requirements. For 380v water-cooled chillers, the dimension may be L*W*H=150*120*180 cm, and the weight is around 450 kg.

- Control System: The chiller's control system, including the type of controller and its functions, such as temperature control, fault monitoring, data logging, remote monitoring, etc., allows precise control and management of the chiller's operation.

Proper maintenance of water 380v chillers is crucial for optimal performance, efficiency, and longevity. Regular maintenance helps prevent breakdowns, reduce operating costs, and ensure the chiller operates safely.

- Regular Inspections: Conduct routine inspections to check for refrigerant leaks, loose electrical connections, worn belts, and any signs of damage or abnormal conditions. Promptly address any issues detected during inspections.

- Cleaning: Keep all components of the water-cooled chiller, including evaporators, condensers, fans, and filters, clean and free from debris. Regular cleaning helps maintain proper heat transfer and airflow.

- Lubrication: Lubricate moving parts, such as fan motors and pump bearings, following the manufacturer's recommendations. Lubrication reduces friction, minimizes wear, and ensures smooth operation.

- Refrigerant Check: Periodically check the refrigerant levels in the chiller to ensure they are within the specified range. Low refrigerant levels can affect cooling performance and indicate leaks that require professional repair.

- Electrical System Maintenance: Inspect the electrical system, including controllers, relays, contactors, and connections, for signs of wear or corrosion. Clean, tighten, and ensure proper electrical connections to prevent electrical faults.

Scenarios of 380v water cooled chillers

High-capacity 380v water cooled chillers are suitable for chilling large-scale applications in different industries. Here are some of the common uses:

-

Food and beverage making

Industries, such as breweries, require powerful chillers to cool down hot wort quickly and keep the production process efficient. Dairy producers also use them to quickly cool milk after pasteurization. Soft drink and ice cream manufacturers use 380v chillers to maintain specific temperatures in their production lines and during storage.

-

Large air conditioning systems

Coolant for centralized air conditioning systems, such as in commercial buildings, shopping centers, hotels, and office buildings. Thanks to their ability to cool huge amounts of water, 380v water cooled chillers are the ideal choice for this application.

-

Plastic and chemical industries

Industries use 380v water cooled chillers to maintain a constant temperature during the injection molding process. They are also used to support chemical reactions, maintain the temperature of equipment, and cool reaction vessels.

-

Laser cutting and machine tool cooling

Laser cutting machines must be kept at a specific temperature to maintain an optimal cutting performance. Chillers do this job for them by absorbing heat generated by the laser tube. Laser machines and CNC machines also use 380v water cooled chillers to maintain their operational efficiency.

-

HVAC systems in data centers

Data centers need to keep their servers and other electronic equipment parts within the required temperature range. The 380v chiller can take away heat from the coolant and reject it to the atmosphere. As a result, it maintains the right temperature inside the building for the proper functioning of all equipment.

-

Medical applications

The medical industry uses 380v chillers in many ways. For instance, they are used to cool MRI machines. Some hospitals or healthcare centers may also use them to refrigerate blood and other medical supplies. In research laboratories, 380v chillers can help control temperature in incubators or chemical reactors.

How to choose 380v water-cooled chillers

Selecting the right water chiller is very important for a business buyer's needs and budget. This is why they need to take the following factors into account:

- Cooling capacity evaluation: It is always important to determine the required cooling capacity first. Calculate the heat load of the equipment or process that needs to be cooled. It is also important to consider factors like the ambient temperature, insulation, and the size of the space. This will help the business buyer in finding a 380v water-cooled chiller with the appropriate cooling capacity.

- Efficiency and performance: The buyer should look for a chiller with a high cooling efficiency per kWh. The chiller should also have a good performance-to-power consumption ratio. In some cases, the buyer's process might benefit from the implementation of variable cooling loads, which can help in allowing the chiller to adjust its cooling capacity based on the actual cooling needs. This, in turn, should improve overall energy efficiency.

- Operating costs: When selecting a chiller, it is important to consider the total operating costs. Do not just focus on the initial purchase cost. Operating factors like energy efficiency, maintenance requirements, and water consumption can have a significant impact on the long-term operating costs of the chiller.

- Environmental impact: Select a chiller that has a high energy conversion efficiency so as to minimize electricity consumption and reduce carbon emissions. It is also important to consider the refrigerant used in the chiller. Refrigerants that do not harm the ozone layer should be selected, and those with low global warming potential should be preferred.

- Noise level: The water-cooled chiller's noise level will matter in some use settings. Consider the chiller's rated noise level and choose a model with a lower noise level if the buyer requires it.

- Chiller type: If a buyer needs to save cost, a cooling tower-based 380v water-cooled chiller should be selected. If, on the other hand, the buyer's need is better energy efficiency, he should go for a water-cooled chiller that uses a screw compressor. It is important to consider all factors to ensure an adequate 380v water-cooled chiller is selected for the process or use case.

Q&A

Q1: What types of chillers are available?

A1: There are air-cooled and water-cooled chillers. The 380v water-cooled chiller is among the most popular industrial chillers.

Q2: What are the benefits of a chilller?

A2: A chiller's primary purpose is to remove heat from a liquid via evaporation. It is also critical in assisting industrial processes, air conditioning systems, and the production of ice.

Q3: How long can a chiller be expected to last?

A3: If properly maintained, a chiller can last for about 20 years.