(289 products available)

A 1micron filter mesh is commonly used in various industrial applications to separate unwanted contaminants from liquids, air, and other gases. The mesh designs incorporate holes or openings, which are used to collect tiny particles measuring 1 micron (1/1000th of a millimeter) or larger. Filter mesh sizes can vary according to the needs of the industry. The following are some common types of 1-micron mesh filters:

1-micron nylon meshes

These filter meshes are produced in different nylon mesh patterns. These are then coated with epoxy or created as flat filters in an oval or round shape. 1-micron nylon filters are used in fuel strainers, air filtration, and straining applications like laboratory reagent.

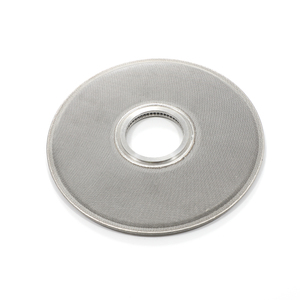

1-micron stainless steel filter mesh

Stainless filter mesh is known for its high tensile strength and ability to resist significant heat and corrosion. It is used in chemical processing, oil refining, filtration, liquid processing, and food manufacturing industries. They are also used to make sturdier filter bags and cartridges.

PP 1-micron filter mesh

The polypropylene (PP) 1-micron filter mesh) is used to manufacture a filter bag or cartridge that captures contaminants in liquids. It is made from durable plastic, offering chemical resistance against inorganic substances.

1-micron brass filter mesh

The brass filter mesh comes in two different grades and is a good option when looking for resistance to saltwater corrosion. The mesh is also very malleable. This makes it possible for manufacturers to easily incorporate or assemble the brass filters within other components.

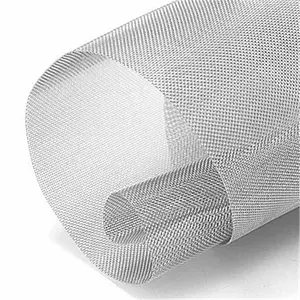

Woven 1-micron filter mesh

Woven filters are made from different materials. The material is either woven or knitted together to form a strong and porous barrier that captures particles. Woven mesh is flexible and lightweight. It is suitable for easy straining where filtration needs are not complicated.

Materials:

1micron filter mesh is usually made of stainless steel, nylon, or polyester. Nylon and polyester offer good chemical resistance. Stainless steel meshes provide structure and durability.

Openings and widths:

1micron filter meshes are available in different sizes. When purchasing a filter mesh, it is essential to check the exact dimensions and openings.

Coatings:

Depending on the application, filter meshes may have additional coatings. For instance, anti-corrosive or protective coatings can prolong the filter's life. Other coatings, such as conductivity or lubricity, may also be beneficial, depending on the intended application.

Mesh patterns:

1micron filter meshes can come in different patterns. Common patterns include twill weaves, plain weaves, and bespoke designs. The choice of mesh pattern affects the filter's efficiency and performance.

1micron filter mesh needs cleaning and maintenance to prolong the filter's service life. The following mesh cleaning methods can help restore the filter's full performance.

Backflushing:

This cleaning method is suitable for 1-micron filter meshes with a cartridge or candle structure. It involves the reversing flow of a cleaning fluid through the filter in intervals. Backflushing dislodges the filtered particles stuck in the mesh. So, it renews the filter's function without dismantling it.

Chemical washing:

In this method, a cleaning solution is passed into the filter mesh. The solution helps to break down grease, scale, and particulates stuck in the mesh. Once the cleaning solution degrades the contaminants, the filter is backflushed.

Soaking:

This method is suitable for mesh filters with a lot of retained contaminants. It involves removing the filter mesh from its housing. Then, soak it in a suitable cleaning solution for a specified time. The solution breaks down and loosens the contaminants. After soaking, the mesh is backflushed to remove the dislodged contaminants.

Filtration system upgrade:

If the filter mesh is overtly fouled and the cleaning methods do not work, a system upgrade may be necessary. It's better to use a bigger filter mesh or an additional filter stage rather than risking system failure.

One micron filter meshes are extensively and widely used in industries and applications that need filtration. Below are some application areas where 1-micron filter meshes are used.

Food and beverage industry

1-micron filter meshes are used in the food and beverage industry to ensure product quality and safety. In breweries and wineries, these filters strain out unwanted particles from beverages like beer, wine, and fruit juices. They're also utilized in food production facilities to filter ingredients such as oils, syrups, and liquids, preventing contaminants from entering the final products.

Aerospace and defense

In sectors like defense and aerospace, the need for precision is unquestionable. Here, 1-micron filter meshes show their ability by filtering lubricants, fuels, and hydraulic fluids used in aircraft, military vehicles, and spacecraft to ensure optimal functioning and eliminate potential contaminants that could compromise performance.

Textile industry

Within the textile domain, materials are subjected to 1-micron filter meshes to eliminate impurities, fibers, and chemicals that could adversely affect product quality. Filtered water, stripped of contaminants, is utilized in textile manufacturing processes, including dyeing and printing, to prevent color and fabric defects.

Environmental protection

Micron filter meshes serve as crucial tools in safeguarding the environment. They find utility in wastewater treatment plants, where they segregate solid waste, sediments, and contaminants from treated water before it is released into natural bodies of water. By doing so, they play a pivotal role in preserving aquatic ecosystems and maintaining environmental integrity.

Energy production

In the realm of energy production, 1-micron filter meshes continue to prove invaluable. They are employed in power plants to filter cooling water, lubricating oils, and fuel used in machinery and generators. By preventing equipment damage and ensuring efficient energy production, these filters help maintain the seamless functioning of power generation systems that meet global energy demands.

Select filter mesh based on the intended use and application needs. First, decide the type of material needed for the application. Choose nylon or polyester for low-cost and low-temperature applications. Opt for stainless steel for high-temperature, high-pressure, or demanding applications. Next, select the filter mesh grid size based on the purpose of using the filter mesh. Select a large grid size if the goal is to achieve maximum flow with minimum filtration. On the other hand, choose a smaller grid size to capture finer particles but expect a reduction in fluid or air flow.

Choose the right filter mesh micron size based on the user needs. A 1-micron filter mesh is ideal for capturing most bacteria,Betaproteobacteria, and protozoa but allowing viruses to pass through. A 5-micron filter mesh is more appropriate for capturing larger microorganisms such as certain bacteria. In some cases, it is better to combine filter meshes with varying micron sizes to achieve a more desirable outcome. Take into consideration the filter mesh aperture shape. Select a round aperture if the goal is to achieve uniform filtration. On the other hand, an oval or slit aperture may work better when trying to achieve maximum strength with a lightweight filament. Also, consider the filter mesh's chemical compatibility. Choose filter mesh material compatible with the chemicals in use to extend filter mesh life.

Finally, select the right filter mesh material thickness for the application. A thick filter mesh provides more durability and strength. A fine filter mesh thickness is preferable when the filter mesh will be used in a low-stress environment or after a short period. In contrast, a thicker filter mesh is better for use in a high-stress environment or where durability is a priority.

Q1: What does 1 micron filter mean?

A1: The filter's size and mesh opening are measured in microns. One micrometer equals 1 millionth of a meter, or 0.001 millimeters. Using this measurement, 1 micron is large enough to allow water molecules to pass through but small enough to block bacteria.

Q2: Is it safe to drink 1-micron filtered water?

A2: Yes, water filtered through a 1-micron filter is safe to drink. The filter is small enough to trap organisms larger than 1 micron, including bacteria, fungi, and algae.

Q3: Do 1-micron filters remove viruses?

A3: Unfortunately, 1-micron filters do not capture viruses. Viruses are smaller than 1 micron and may pass through the filter. A sub-micron filter, however, could capture viruses.

Q4: What are the benefits of using a filter mesh?

A4: Filter meshes have great benefits depending on their size, durability, and mesh count. 1-micron filter meshes prevent the passage of contaminants like bacteria and parasites, offering considerable health benefits. They are also cost-effective and sustainable, as they reduce the need for chemical water treatments and can be used in various applications.