(118 products available)

This section will focus on the measurement and correlation of gauge and thickness, emphasizing the relevance of the 16-gauge galvanized wire thickness in many applications.

The wire gauge system is extensive and is primarily used to denote the diameter of a wire. The smaller the gauge number, the thicker the wire. For instance, 16-galvanized wire, measured through the American Wire Gauge (AWG) system, is approximately 0.0508 inches or 1.29 mm in diameter.

Galvanized wire is a type of wire that paves the way for enhanced corrosion resistance due to its zinc coating. This aids in prolonging the durability of the wire in exposed surroundings.

Thickness is a salient element of wire gauge in that it directly affects tensile strength, flexibility, and electrical carrying capacity. As a rule of thumbs, thicker wires provide greater strength and can withstand saunter before bending or breaking. The 16-galvanized wire strikes an exquisite balance, rendering it malleable while remaining robust enough to undertake demanding tasks.

This gauge wire is standard in fencing material, as it brings forth an ideal blend of resilience and yield strength, withstanding the weight of animals or objects and the strains of environmental exposure.

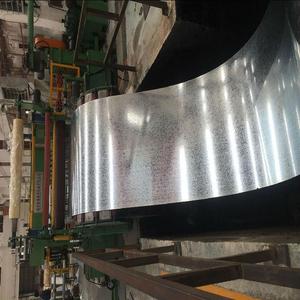

Galvanized wire is flexible steel wire. To expand its durability and functionality, it undergoes a galvanization process, whereby a zinc coating is applied to steel through systematic techniques such as hot-dip or electro-galvanization.

Steel: Steel is renowned for its strength and versatility. It gives 16-galvanized wires, which can withstand severe pressure and, therefore, are best in fencing, construction, and crafts. With notable tensile strength, the wire effectively resists deforestation under heavy loads. While soft steel is usually chosen for vehicle applications, high carbon steel may be ideal for tools.

Galvanization: Zinc acts as a metal protection layer against rust and corrosion for galvanized wire exposure to moisture and environmental elements. This is particularly indispensable for outdoor applications where weather conditions would deteriorate conventional non-coated wires. The gauge wire thickness for auto parts and tools is selected from levels that allow them to resist bending and frequent pressure.

Durability: 16-galvanized wire is manufactured to be a stalwart and long-lasting material for outdoor uses. The galvanized coating aids in the prevention of corrosion for several years, even in environmental settings, with humidity and precipitation as the order of the day. Additionally, steel wire is sturdy and flexible; the wire can be bent or shaped without breaking. When a product has durability, it becomes reliable for tasks like tensioning fences, wire constructing supports, and mesh.

The materials and processes employed in creating this wire render it a reliable and durable solution to many applications necessitating fierce resistance to the elements and physical wear.

The versatility of 16-galvanized wire makes it ideal for several uses, ranging from agriculture and manufacturing to DIY projects and construction work.

When participating in 16-gauge galvanized wire activities, it is critical to choose wire of quality and applications in which wire strength is essential. The following factors should be considered carefully:

Wire quality and strength consideration guarantee wire that will perform effectively and reliably in its intended application. This is especially true for galvanized wires designed for outdoor use.

A1: The ultimate tensile strength for this wire can differ by wire material and thickness, although it generally varies between 650 and 800 pounds.

A2: The wire is about 0.0508 inches in diameter, with a gauge number of 16 according to the American Wire Gauge system.

A3: While it can carry the current; it is not predominantly applied in electrical settings due to the availability of coils.

A4: It can be molded multiple times without breaking. Therefore, it is ideal for fencing due to minimal wear on the wire.