(4502 products available)

Adhesive roof membranes are single-ply roofing membranes with self-adhesive backing. They are widely used in commercial buildings for waterproofing and weatherproofing. The construction of an 1.2mm adhesive roof membrane includes a TPO, PVC, or EPDM membrane, a layer of insulation, a polyester fleece backing, and a self-adhesive glue. Here are the types of adhesive roof membranes:

TPO Adhesive Roof Membrane

TPO stands for Thermoplastic Olefin. A TPO adhesive roof membrane is made from polypropylene, rubber ethylene, and plastic. They are popular among building owners because they are cheaper than other options. TPO roofing has a white surface, which helps reflect UV rays and keep buildings cool. The roofs are mechanically attached or fully adhered to an insulated roof deck.

PVC Adhesive Roof Membrane

A PVC roof membrane is made from polyvinyl chloride, a chemical that includes UV stabilizers and fire retardants. The roof membranes are popular because they are durable and long-lasting. They can last up to 30 years with proper maintenance. Their bright white color helps reflect the sun and lower energy costs.

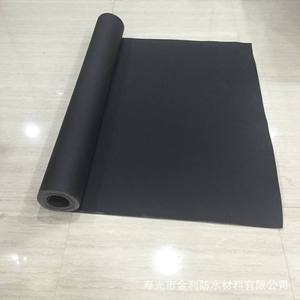

EPDM Adhesive Roof Membrane

EPDM stands for Ethylene Propylene Diene Monomer. An EPDM roof membrane is made from synthetic rubber. They are popular due to their affordability. EPDM membranes are cheaper than TPO or PVC. They offer excellent weather resistance. EPDM works well in different climates, whether hot, cold, or rainy. They are available in black or white. The black color absorbs heat, while the white color reflects it.

Self-Adhering Roof Membrane

A self-adhering roof membrane is made with a durable polyethylene film. The polyethylene film is bonded to the membrane using a high-quality adhesive. The adhesive is covered with a release liner. Once the release liner is removed, the membrane can be firmly adhered to the substrate. Self-adhering membranes install quickly and easily. They don't require additional adhesives or solvents. This helps reduce labor costs and installation time. They offer excellent wind uplift resistance. The adhesion is strong, which minimizes the risk of wind damage.

The adhesive roof membrane is designed to enhance sustainability in construction and building industries. Its features and functions are as follows:

Durability

The 1.2mm adhesive roof membrane is durable and offers long-term protection for buildings. It can withstand harsh weather conditions like heavy rains, strong winds, and UV radiation. This is because it is made of high-quality materials like reinforced PVC or TPO. Its membranes can resist tears, punctures, and cracks, which protects roofs from leaks and damage. Their durability provides an opportunity for building owners to save costs due to low maintenance requirements and frequent repairs. These membranes also last for decades, which protects the structural integrity of buildings.

Easy installation

The 1.2mm roof membrane is simple to install due to its self-adhesive backing. This enhances the efficiency and speed of the installation process since no additional adhesives are required. Its installation does not require skilled labor, which reduces overall roof construction costs. The self-adhesive membrane leads to a stronger bond, which creates a seamless and durable roof.

Waterproofing

The adhesive roof membrane provides excellent waterproofing. Its self-adhesive nature and seam-weld techniques create a continuous and seamless roofing surface. This minimizes water pooling, which prevents leaks and water infiltration. The roof membrane repels water due to its synthetic material that offers a waterproof barrier.

Energy efficiency

The adhesive roof membrane enhances energy efficiency. Its materials, such as TPO, have reflective properties that deflect sunlight and reduce heat absorption. This helps in keeping the building cool, which reduces reliance on air conditioning systems. The energy-efficient roof systems lower energy bills and promote sustainable building practices.

Environmental sustainability

The 1.2mm adhesive roof membrane promotes environmental sustainability. Its materials are recyclable, which reduces waste disposal problems at the end of their lifecycle. Some roofs have solar panels that promote renewable energy generation. The light-colored roofs enhance the urban heat island effect by reducing temperatures in urban areas.

The 1.2mm adhesive roof membrane is used in various industries. Here are some of the scenarios where it is widely used:

Choosing the right adhesive roof membranes involves considering various factors. Here are some of them:

Consider the Roof Pitch

Flat roofs are pitched roofs that work well with adhesive membranes. However, a 1.2mm thick membrane can also be used on a slightly sloped roof. A thicker membrane is stable and won't easily tear or puncture. The building owner can use a reinforced membrane on a sloped roof to prevent folding during installation.

Evaluate the Local Climate

The local climate will influence the choice of an adhesive roof membrane. For areas with high winds, select a membrane with high tensile strength. A strong membrane can withstand wind pressure and won't tear or damage. For regions with heavy rain, consider a membrane with excellent waterproofing features. A membrane with high puncture resistance is ideal for areas with high foot traffic.

Assess the Building Type

The type of building will influence the choice of adhesive roof membrane. For residential buildings, a membrane with excellent waterproofing, UV resistance, and durability features is ideal. For commercial and industrial buildings, consider a membrane with high tensile strength and durability. A commercial building's roof may have more equipment than a residential building, leading to potential punctures.

Consider the Budget

The budget influences the choice of adhesive roof membrane. Premium membranes have higher prices, but they are durable and need minimal maintenance. Standard membranes are more affordable but may need frequent maintenance. When working on a tight budget, consider a standard membrane, but choose a premium one for a more extensive building project.

Evaluate Ease of Installation

For those with roofing experience, consider a membrane that is easy to install. Most manufacturers provide an installation guide that shows the steps involved in the process. Consider the installation time and technique when choosing a membrane. Single-ply membranes are ideal since they are lightweight and easy to install.

Evaluate the Manufacturer's Reputation

Before purchasing an adhesive roof membrane, research the manufacturer's reputation. Consider reading reviews from previous customers. Select a manufacturer that delivers quality products.

Q1: How long will a 1.2mm adhesive membrane roof last?

A1: An adhesive membrane roof lasts up to 30 years or more. However, this depends on factors such as proper installation, quality of materials, and climate conditions.

Q2: How is a roof membrane installed?

A2: First, clean and prepare the surface. Roll out the membrane adhesive and allow it to become tacky. Then, lay the membrane, ensuring there are no air bubbles or wrinkles. Secure the edges and overlaps using adhesive or mechanical fasteners. The membrane should be installed by professionals to ensure it is done correctly.

Q3: What is the difference between a roof membrane and a roof mat?

A3: A roof membrane is a thin layer of material that provides a waterproof barrier. A roof membrane acts as a waterproof barrier but is thicker and often used for additional protection or insulation.